The Future of Product Development: Why You Need a Plastic Prototype Manufacturer

In today's fast-paced business environment, staying ahead of the competition requires innovation, efficiency, and precision. As a result, the role of a plastic prototype manufacturer has never been more critical. These specialized companies enable businesses to transform their ideas into tangible products through advanced prototyping techniques. In this extensive guide, we will delve into the numerous advantages of working with a plastic prototype manufacturer and how it can significantly impact your product development cycle.

Understanding the Role of a Plastic Prototype Manufacturer

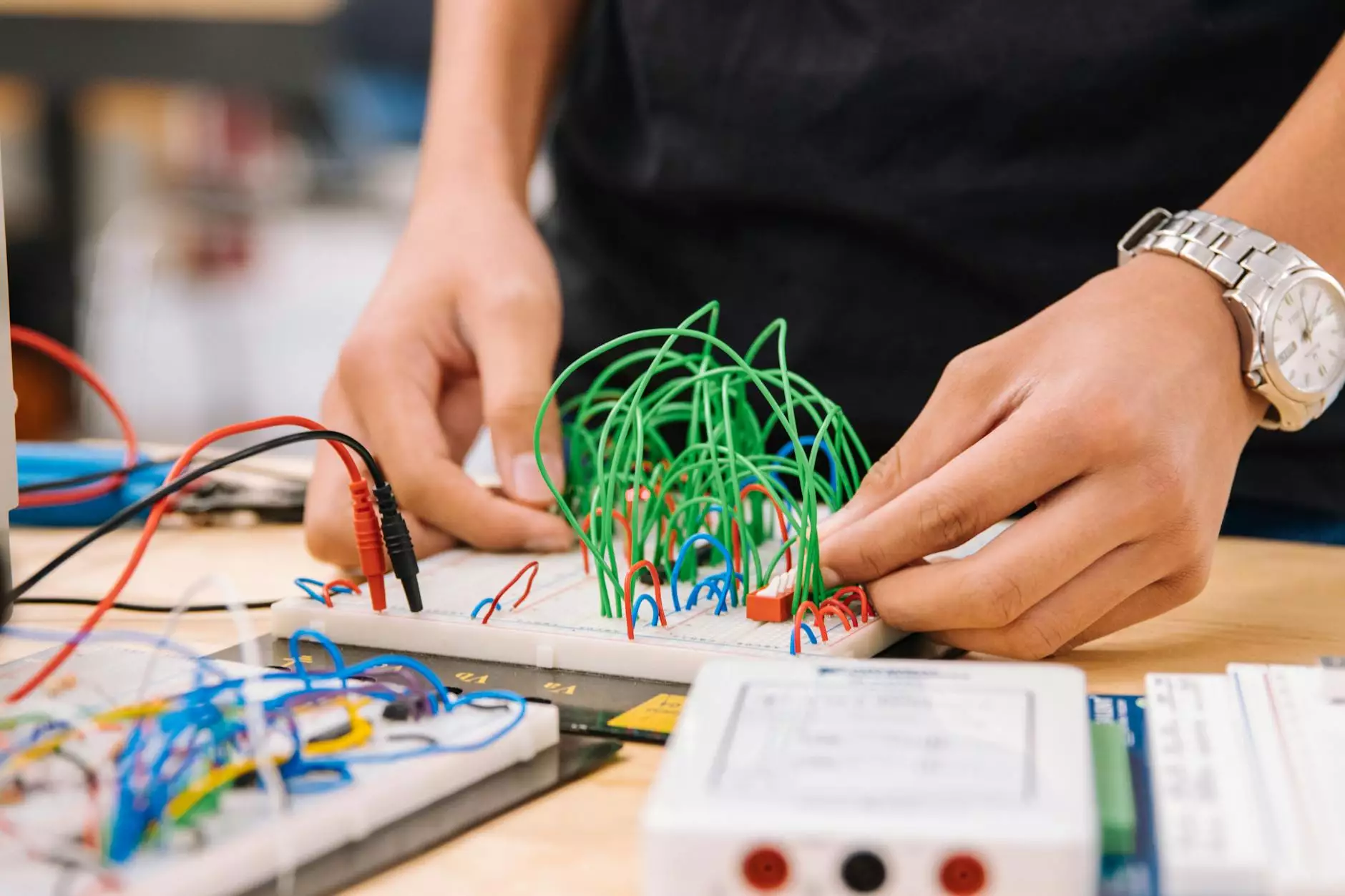

A plastic prototype manufacturer serves as a bridge between conceptual designs and finished products. Using state-of-the-art technology and materials, these manufacturers create prototypes that closely resemble the final product, allowing businesses to test, evaluate, and refine their designs before moving into mass production.

Key Functions of a Plastic Prototype Manufacturer

- Rapid Prototyping: Speeding up the development process by quickly creating and modifying prototypes.

- Material Selection: Offering a wide range of plastic materials suited for various applications.

- Precision Engineering: Utilizing advanced machinery to ensure high accuracy in prototype dimensions.

- Design Validation: Enabling businesses to validate their designs through testing and feedback.

- Cost Efficiency: Reducing the costs associated with design errors and late-stage modifications.

The Advantages of Using a Plastic Prototype Manufacturer

Utilizing the services of a plastic prototype manufacturer brings a host of benefits to any business looking to innovate. Below are some of the most significant advantages:

1. Enhanced Product Design and Development

When businesses engage with a plastic prototype manufacturer, they gain access to expertise and technology that can significantly enhance product design. With rapid prototyping tools, designers can create multiple iterations of a product quickly, allowing for:

- Immediate feedback from stakeholders.

- Incorporation of user testing results into the design.

- Refinement of aesthetics and functionality based on real-world application.

2. Reduced Time to Market

In industries where timing is everything, a plastic prototype manufacturer can shave essential weeks or even months off the product development timeline. By streamlining the prototyping process, businesses can:

- Launch products faster than competitors.

- Respond swiftly to market demands and trends.

- Capitalize on emerging opportunities without delay.

3. Improved Communication Among Teams

Prototypes serve as common reference points for engineering, marketing, and design teams. When everyone can visualize and interact with a physical model, communication improves significantly. This leads to:

- Fewer misunderstandings regarding product specifications.

- Better alignment of team goals and objectives.

- Increased collaboration across departments.

4. Cost Savings in the Long Run

While the initial investment in prototyping can seem high, the costs associated with late-stage design changes are significantly higher. A plastic prototype manufacturer helps mitigate these costs through:

- Identifying design flaws early in the development process.

- Avoiding expensive production modifications.

- Reducing the risk of product recalls due to defects.

How to Choose the Right Plastic Prototype Manufacturer

Choosing the right plastic prototype manufacturer is crucial for your project's success. Here are some factors to consider:

1. Experience and Expertise

Look for a manufacturer with a proven track record in producing high-quality prototypes. Check their portfolio and client testimonials to assess their capabilities.

2. Range of Services

Ensure the manufacturer offers a comprehensive suite of services, including various prototyping techniques such as:

- Stereolithography (SLA)

- Selective Laser Sintering (SLS)

- Fused Deposition Modeling (FDM)

- Injection Molding

3. Material Options

The best plastic prototype manufacturers provide a wide array of material options to suit different applications. This flexibility can assist you in achieving the desired product characteristics.

4. Prototyping Technology

Advanced technology leads to better precision and faster turnaround. Research the machinery and techniques the manufacturer employs to ensure they can meet your needs.

5. Customer Support

Effective communication and support during the prototyping process can make a significant difference. Choose a manufacturer who is responsive and willing to collaborate closely with your team.

Industry Applications of Plastic Prototyping

Plastic prototypes are widely used across various industries. Understanding these applications can help highlight the versatility and benefits of collaborating with a plastic prototype manufacturer.

1. Consumer Products

From electronics to everyday household items, consumer products often undergo extensive prototyping to ensure functionality and appeal. Manufacturers help brands test ergonomics, aesthetics, and user interfaces.

2. Automotive Industry

The automotive sector relies heavily on plastic prototypes for both interior and exterior components. Prototyping allows for rigorous testing of durability and performance under real-world conditions.

3. Medical Devices

In the medical field, the stakes are incredibly high. Prototyping accelerates the development of devices such as surgical tools and diagnostic equipment, helping ensure safety and efficacy before mass production.

4. Aerospace

The aerospace industry utilizes plastic prototyping for components that require lightweight, durable materials. Prototypes are crucial in validating designs that will withstand high-pressure environments.

5. Industrial Equipment

Manufacturers of industrial machinery often use prototypes to refine their designs, improve workflows, and ensure safety features are effectively integrated.

Conclusion

In conclusion, collaborating with a plastic prototype manufacturer is increasingly vital in today’s competitive marketplace. The advantages of rapid prototyping—such as enhanced product design, reduced time to market, improved team communication, and long-term cost savings—cannot be overstated. By selecting the right manufacturer, businesses can not only bring their innovative ideas to life but also position themselves ahead of the competition in their respective industries.

At Deep Mould, we specialize in providing high-quality prototyping services tailored to your needs. Our expertise in various industries coupled with our state-of-the-art technology ensures that your vision becomes a reality efficiently and effectively. Contact us today to start your journey towards successful product development!